French Fry Cattaneo

Sunday, June 28, 2015

Thursday, March 5, 2015

Volvo 940 Homemade Valve Spring Compressor

Unfortunately these will not work on a 8v redblock engine because the valve springs are recessed into the head and you can't grab onto the outside of them. There are two other common types of valve spring compressors you can buy, one that looks like a giant c-clamp and another one that attaches to one of the studs on top of the engine and uses that as leverage to press on the valve spring. Both of these would have worked on my engine but they weren't available for rent and cost around $100-$200 locally. Since they are a very simple design I thought I'd build my own. This is the style I modeled it after:

It consists of a raised bar which bolts to the valve cover studs. From this bar there is a lever which compresses the valves, and it can slide back and forth to easily move from one valve to the next.

Here's what it looks like:

It's mostly made of steel scraps. The only part I bought was the wheel which provides a nice smooth action when compressing the springs.

The part that actually presses on the valves is an oxygen sensor socket (the cutout gives you access to the valve keeper) with a couple adapters on top to get it to be the right length.

To use it all you do is position it over the valve, press down, and remove the keepers using a magnet-on-a-stick.

Monday, August 25, 2014

Built in Software Defined Radios on a Toughbook CF-30

I've been playing with the RTLSDR radios and have been wanting to build them into a computer. My toughbook was perfect for this because it has tons of space inside for the various expansion bays that I'm not using. The media pocket (where the cd drive would go if you had one, I just use a usb cd drive on the rare occasion I need to use a cd), pcmcia, and expresscard slots are all next to each other and leave a lot of space for addons. I took the case off a small 4 port USB hub and installed it in the case with a RTLSDR dongle and a funcube dongle, although you could use two (or more) RTLSDRs if you wanted.

I then cut the plug off the usb cable going into the hub and soldered it onto the pins for one of the usb plugs on the back. This means I lose one of the usb ports, if you wanted to be cleaner I'm sure there's an internally used usb port that you could tap into that goes to the docking connector.

From the RTLSDR the antenna connector goes to a SMA connector mounted on the door. I used a flange mount SMA connector because I was having trouble with the more common type that just mount with a nut.

The Funbcube uses the built in pull out antenna that was originally hooked up to the cellular modem. It's tuned for cellular frequencies (something like 850-1900 mhz) which works pretty well for the control channel trunking frequencies which are in the 700-900 mhz range. It is a tiny antenna but it works great for the local police trunked system. I bought a SMA to U.FL connector so I could plug the antenna in with no modification. Also it hooks through the rear docking connector so if I got a dock I could have it connected to a larger external antenna. The funcube doesn't have much bandwidth (96khz instead of the 2 mhz on the RTLSDR) but is perfect for parking on one frequency while I use the RTLSDR to look for new signals.

There are a few downsides to this, mainly putting them unshielded next to a computer motherboard exposes them to a lot of RF interference, I'm sure it's raising my noise floor significantly. If I was more concerned I'd look into covering them in metal foil and maybe adding some ferrite beads, but I've found the performance to be more than adequate for the strong signals I receive. Besides, if you really want to get the best performance you're much better off physically isolating the sdr in a separate metal box.

I then cut the plug off the usb cable going into the hub and soldered it onto the pins for one of the usb plugs on the back. This means I lose one of the usb ports, if you wanted to be cleaner I'm sure there's an internally used usb port that you could tap into that goes to the docking connector.

From the RTLSDR the antenna connector goes to a SMA connector mounted on the door. I used a flange mount SMA connector because I was having trouble with the more common type that just mount with a nut.

The Funbcube uses the built in pull out antenna that was originally hooked up to the cellular modem. It's tuned for cellular frequencies (something like 850-1900 mhz) which works pretty well for the control channel trunking frequencies which are in the 700-900 mhz range. It is a tiny antenna but it works great for the local police trunked system. I bought a SMA to U.FL connector so I could plug the antenna in with no modification. Also it hooks through the rear docking connector so if I got a dock I could have it connected to a larger external antenna. The funcube doesn't have much bandwidth (96khz instead of the 2 mhz on the RTLSDR) but is perfect for parking on one frequency while I use the RTLSDR to look for new signals.

There are a few downsides to this, mainly putting them unshielded next to a computer motherboard exposes them to a lot of RF interference, I'm sure it's raising my noise floor significantly. If I was more concerned I'd look into covering them in metal foil and maybe adding some ferrite beads, but I've found the performance to be more than adequate for the strong signals I receive. Besides, if you really want to get the best performance you're much better off physically isolating the sdr in a separate metal box.

Monday, June 23, 2014

Volvo 940 grill repainting

The plastic front grill on my 940 was looking faded and beat up so I decided to refurbish it. I scrubbed it with soap and water and painted it semi-gloss black with rustoleum "ultra cover" which claims to work on plastic. Plastic is very hard to get paint to adhere to correctly, so make sure to get paint designed specifically for plastic. The most common brand of plastic compatible paint is krylon fusion, but they don't have that at my hardware stores. You could also use plasti-dip if you want to remove it later or like that look.

After the paint dried the spot where the volvo logo was looked weird so I ordered a prancing moose sticker from Dave Barton Volvo. They have about a million different sticker options. The moose comes from a famous volvo safety test that involves dodging a moose at speed. Here's how it looks:

The display in the bottom left is the voltmeter for my welder.

I also installed an anti-theft system from the same site:

After the paint dried the spot where the volvo logo was looked weird so I ordered a prancing moose sticker from Dave Barton Volvo. They have about a million different sticker options. The moose comes from a famous volvo safety test that involves dodging a moose at speed. Here's how it looks:

The display in the bottom left is the voltmeter for my welder.

I also installed an anti-theft system from the same site:

Thursday, June 12, 2014

Panel labeling

One of the tricky parts of many projects is labeling the controls or buttons on your front panel. A new way I've been trying out is using rub-on dry transfer letters. Basically you get a transparent sheet of paper with letters and numbers on it and you transfer them to your panel (can be pretty much any material, including painted surfaces) by rubbing them. You can get tons of different fonts and font sizes, and even symbols. I got a few sheets of it off ebay for about $10. Here is a picture of it and the bamboo skewer I use to rub them on. They recommend using a pencil, but the skewer seems to work well.

The project I'm working on right now is the remote control panel for my engine driven welder, here is a picture of what I started with:

And here it is with the letters applied:

The letters stay on pretty well by themselves but for something like this where it will be exposed to abrasion I decided to put a clearcoat over it, in this case I'm using rustoleum clear enamel. I'd recommend testing what you're using to put over it, because I originally tried rustoleum rust inhibitor designed for metal and after it dried the letters just rubbed off.

Here is the panel with the enamel and the switches installed:

Here is another example I made for my air compressor. Some of the longer words can be tricky, you can see I didn't quite line up the letters in "overheat".

The project I'm working on right now is the remote control panel for my engine driven welder, here is a picture of what I started with:

And here it is with the letters applied:

The letters stay on pretty well by themselves but for something like this where it will be exposed to abrasion I decided to put a clearcoat over it, in this case I'm using rustoleum clear enamel. I'd recommend testing what you're using to put over it, because I originally tried rustoleum rust inhibitor designed for metal and after it dried the letters just rubbed off.

Here is the panel with the enamel and the switches installed:

Here is another example I made for my air compressor. Some of the longer words can be tricky, you can see I didn't quite line up the letters in "overheat".

Sunday, June 1, 2014

Engine driven welder part 1

This is the first of several posts on my project to create an engine driven welder on my volvo 940. The basic idea is that a regular automotive alternator with it's regulator removed can create enough voltage and current for welding. This is a common project for off-roaders and googling "alternator welder" reveals lots of information, including kits. However I wanted to take it one step further than normal off-roaders and build a real control circuit with voltage regulation, as well as a multi-process machine that could do stick, mig, and tig. I got started with the website http://diy-welder.com/, which documents building a fancier control circuit using analog circuits. I took a lot of useful information from there, but decided to use Atmega328 microcontrollers instead.

The first step of this project was buying an alternator. I picked up a used leece neville 200 amp alternator off a school bus which was a great starting point because it has no built in regulator or diodes (rectifier). You can use any alternator, but you'll have to remove those components. Controlling the voltage output of the alternator is simple, the more voltage you put into the field coil the more voltage comes out of the alternator. Then the 3-phase ac output of the alternator is rectified using diodes (you need ones that can handle the high voltage spikes that come from arc welding, which is why you need to replace the built in ones) and with that alone you're read to stick weld. Mig and Tig are done by adding on a wire feeder, gas solenoid, and control circuitry. For feedback to the microcontroller, I'm using a voltage divider into the ADC to measure voltage and an allegro 200 amp hall effect voltage sensor to measure current. You'll notice on the diagram that the micro doing measurements has an isolated power supply, this is to completely isolate the welder output from the car's 12v system. This isn't strictly necessary, but it reduces the chance of a high voltage spike frying the electronics in my car.

This picture shows the alternator installed where the AC compressor used to be. I fabricated a new mounting bracket which reused the old tensioner. My car has v-belts, which makes this install very easy. It's not impossible to do this on an engine with serpentine belts, but it's more difficult.

Next I ran large gauge cables (I think 2 gauge, although I'm not sure, see note below) from the alternator to the rectifier. The rectifier I used was one out of an old welder I bought on ebay, and is rated for 200 amps. It also came with a nice aluminum frame. It was the perfect size to fit in front of the radiator. One thing to note, it came with MOVs (the surge protector part of a surge protector) which absorb voltage spikes. The MOVs it came with were trashed (scorch marks on the outside) and needed to be replaced. This will increase the life of the diodes. I then added 2 motor start capacitors to the output of the rectifier, about 15 or 20 uf each, which I got from habitat for humanity. Finally, I added a temperature switch out of an old microwave which turns on the cooling fan if the aluminum frame gets too hot. I've since discovered this is unnecessary since the engine idling heats up pretty fast and turns on the fan itself.

From there the output goes through a inductor (simply the wire wound through a microwave transformer a few times) to the quick disconnects mounted on the air dam.

That's about all I have now, it works as a basic stick welder putting out about 100 amps with 1/8" 7018. Next up is to build the control electronics and remote control.

A note about wire gauge:

For automotive applications it is essential to use stranded wire to prevent wire fatigue from vibrations. However not all stranded wire is the same. Welding cable like the kind going to your stringer uses many small strands to create a very flexible cable. Commercial stranded cable usually has fewer, larger strands. The more strands you have, the more flexible the cable is. However, it increases the overall size of the cable. For inside the car, I used stranded cable from the bulk section of home depot, which has very few large strands. It's not that flexible but is much smaller than normal welding cable, making it easier to run throughout the car. The cable in the pictures may not look as large as you're used to, but it has the same amount of copper as more flexible cable.

The first step of this project was buying an alternator. I picked up a used leece neville 200 amp alternator off a school bus which was a great starting point because it has no built in regulator or diodes (rectifier). You can use any alternator, but you'll have to remove those components. Controlling the voltage output of the alternator is simple, the more voltage you put into the field coil the more voltage comes out of the alternator. Then the 3-phase ac output of the alternator is rectified using diodes (you need ones that can handle the high voltage spikes that come from arc welding, which is why you need to replace the built in ones) and with that alone you're read to stick weld. Mig and Tig are done by adding on a wire feeder, gas solenoid, and control circuitry. For feedback to the microcontroller, I'm using a voltage divider into the ADC to measure voltage and an allegro 200 amp hall effect voltage sensor to measure current. You'll notice on the diagram that the micro doing measurements has an isolated power supply, this is to completely isolate the welder output from the car's 12v system. This isn't strictly necessary, but it reduces the chance of a high voltage spike frying the electronics in my car.

This picture shows the alternator installed where the AC compressor used to be. I fabricated a new mounting bracket which reused the old tensioner. My car has v-belts, which makes this install very easy. It's not impossible to do this on an engine with serpentine belts, but it's more difficult.

Next I ran large gauge cables (I think 2 gauge, although I'm not sure, see note below) from the alternator to the rectifier. The rectifier I used was one out of an old welder I bought on ebay, and is rated for 200 amps. It also came with a nice aluminum frame. It was the perfect size to fit in front of the radiator. One thing to note, it came with MOVs (the surge protector part of a surge protector) which absorb voltage spikes. The MOVs it came with were trashed (scorch marks on the outside) and needed to be replaced. This will increase the life of the diodes. I then added 2 motor start capacitors to the output of the rectifier, about 15 or 20 uf each, which I got from habitat for humanity. Finally, I added a temperature switch out of an old microwave which turns on the cooling fan if the aluminum frame gets too hot. I've since discovered this is unnecessary since the engine idling heats up pretty fast and turns on the fan itself.

From there the output goes through a inductor (simply the wire wound through a microwave transformer a few times) to the quick disconnects mounted on the air dam.

That's about all I have now, it works as a basic stick welder putting out about 100 amps with 1/8" 7018. Next up is to build the control electronics and remote control.

A note about wire gauge:

For automotive applications it is essential to use stranded wire to prevent wire fatigue from vibrations. However not all stranded wire is the same. Welding cable like the kind going to your stringer uses many small strands to create a very flexible cable. Commercial stranded cable usually has fewer, larger strands. The more strands you have, the more flexible the cable is. However, it increases the overall size of the cable. For inside the car, I used stranded cable from the bulk section of home depot, which has very few large strands. It's not that flexible but is much smaller than normal welding cable, making it easier to run throughout the car. The cable in the pictures may not look as large as you're used to, but it has the same amount of copper as more flexible cable.

Friday, May 30, 2014

Volvo 940 trailer wiring adapter

I recently picked up a hitch receiver for cheap off craigslist for my 940 with the intention of using it for a bike rack. However I figured I might as well wire up a trailer lighting connector in case I wanted to rent a uhaul. Buying the common 4-pin connector is cheap and hooking it up is pretty simple, except I needed to convert from 5 wire (ground, taillights, brake lights, left turn and right turn) to 4 wire (ground, taillights, combined left turn and brake, combined right turn and brake). European cars usually have separate turn and brake lights, which needs to be adapted to the combined turn and brake lights used on trailers. You can buy adapters that do this but they're kinda expensive ($20+) and draw their current from your car's taillight wiring, which can overload them if your trailer doesn't have led lights. You can add isolation relay to draw power from a separate 12v source but that adds more cost onto the lighting adapter itself.

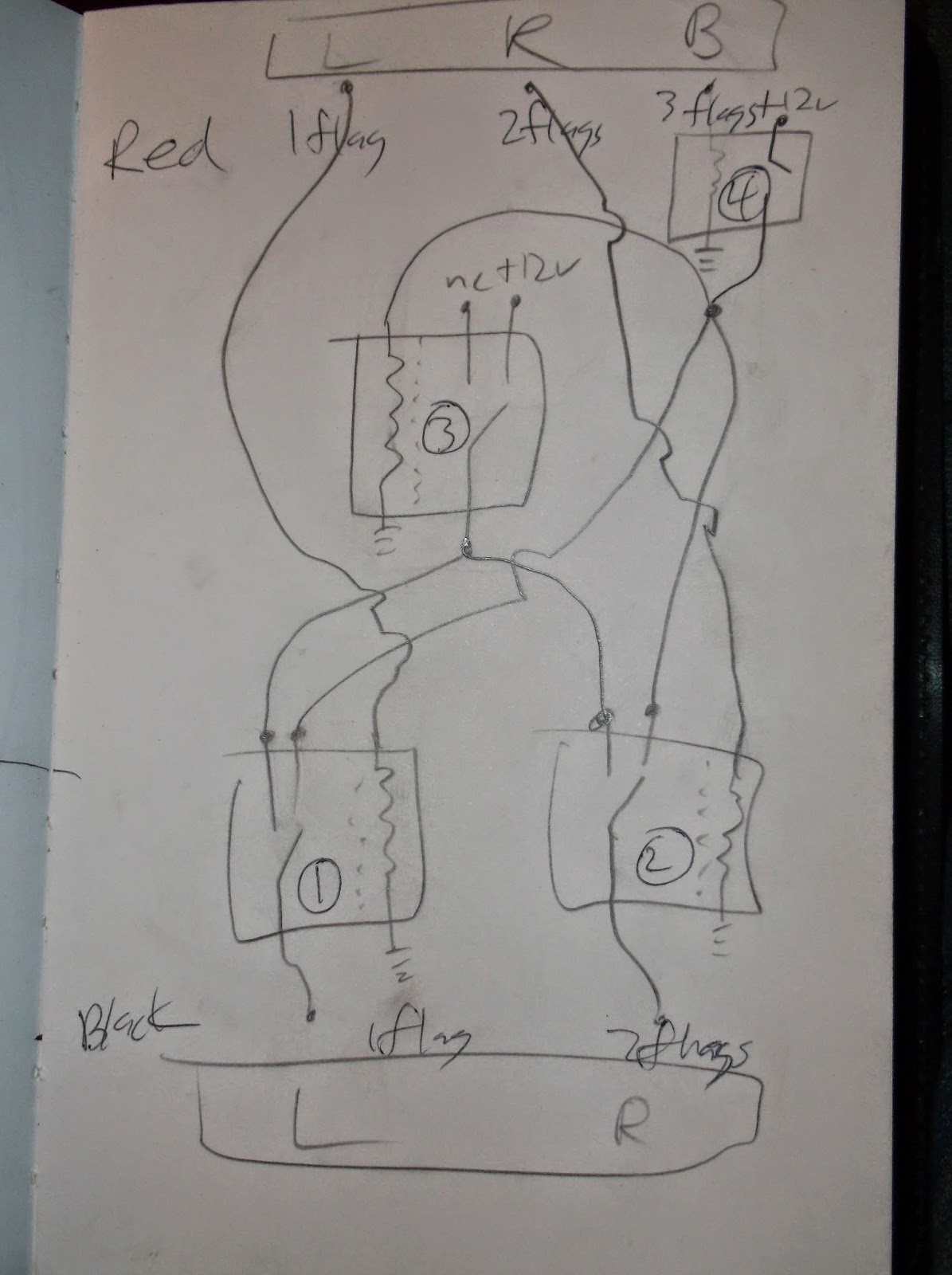

Instead, I built my own trailer adapter using relays that adapts the wiring and provides relay isolation. It requires 5 relays which I purchased from amazon for about $15 including sockets. These are cheap chinese relays, but quality relays cost $15+ each and are unnecessary considering how infrequently I will be using these, if ever. Above is the wiring diagram, which doesn't show the taillight relay. The taillight relay is wired up very simply, with the taillight bulb wire going into the coil and the NO output going to the trailer connector. The rest of the wiring follows the diagram, +12v goes to a fused 12v line running directly to the battery. I fused it at 10 amps which may be higher than necessary but I used wiring that can handle more than 10 amps. Ground should either go to a bolt going into the sheet metal or the grounding bus the lights attach to. As far as tapping into the lights themselves, I used test light (multimeter would work too) to find out which wires were which lights and tapped in at the rear light cluster. If you just hook in directly it will set off the bulb failure relay, but you can compensate for this by adding a resistor equal to the coil of the relay to the bulb on the opposite side of the car. Because the relays are in sockets I remove them all when I'm not towing because I want to extend the life of the relays (chinese relays don't last long under constant use) and because I didn't bother to add the resistors to turn off the bulb failure light.

Instead, I built my own trailer adapter using relays that adapts the wiring and provides relay isolation. It requires 5 relays which I purchased from amazon for about $15 including sockets. These are cheap chinese relays, but quality relays cost $15+ each and are unnecessary considering how infrequently I will be using these, if ever. Above is the wiring diagram, which doesn't show the taillight relay. The taillight relay is wired up very simply, with the taillight bulb wire going into the coil and the NO output going to the trailer connector. The rest of the wiring follows the diagram, +12v goes to a fused 12v line running directly to the battery. I fused it at 10 amps which may be higher than necessary but I used wiring that can handle more than 10 amps. Ground should either go to a bolt going into the sheet metal or the grounding bus the lights attach to. As far as tapping into the lights themselves, I used test light (multimeter would work too) to find out which wires were which lights and tapped in at the rear light cluster. If you just hook in directly it will set off the bulb failure relay, but you can compensate for this by adding a resistor equal to the coil of the relay to the bulb on the opposite side of the car. Because the relays are in sockets I remove them all when I'm not towing because I want to extend the life of the relays (chinese relays don't last long under constant use) and because I didn't bother to add the resistors to turn off the bulb failure light.

Subscribe to:

Comments (Atom)